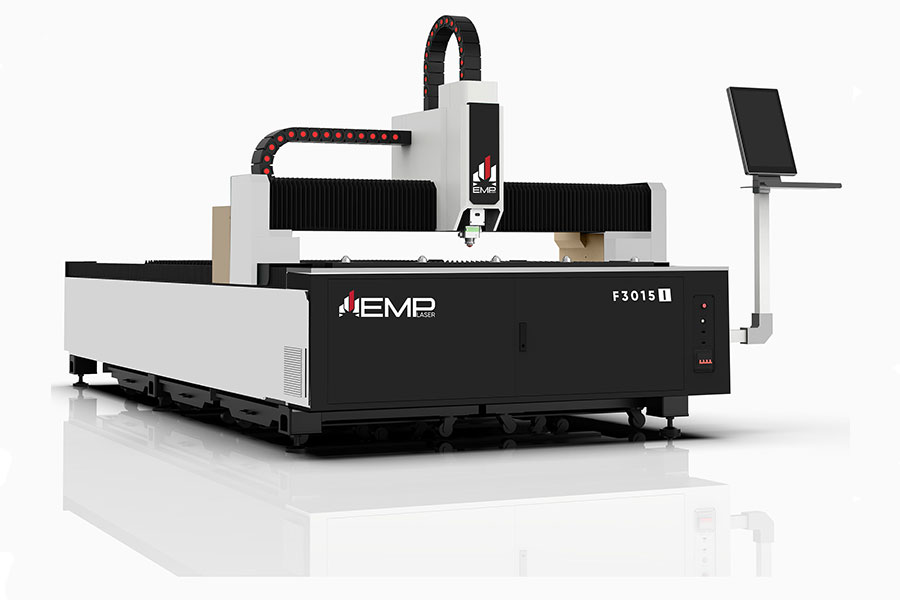

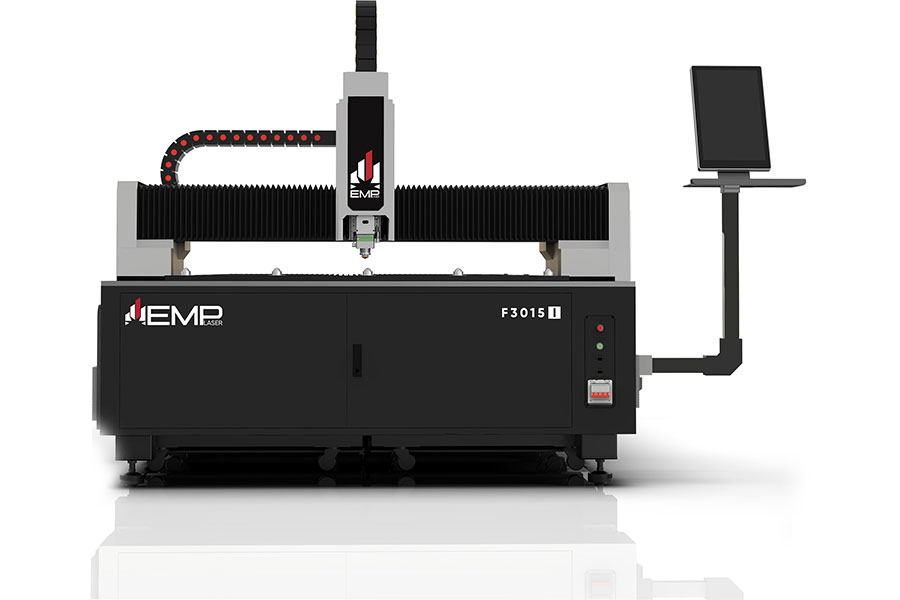

Double-Keel Bed Structure

The EMP F3015’s unique double-keel bed structure supports thick plate processing without deformation, ensuring stable, long-term operation. This is ideal for heavy-duty tasks, providing structural integrity and reliable performance over years of use.

Modular Table Design

The modular design of the table allows for easy assembly, replacement, and maintenance. It ensures a stable work surface that can withstand heavy loads, offering convenience for operators and prolonging the machine’s lifespan.

Advanced Dust Removal System

The F3015’s large-diameter air duct and partitioned dust removal design improve efficiency in removing smoke and heat, ensuring a clean working environment and preserving machine components.

Open-Platform Structure

A single-platform, open structure allows for multi- directional loading, making material handling easy and efficient.

Integrated Safety Features

Intelligent pressure control, anti-collision sensing, and automatic shut-off mechanisms provide added safety and protect both the operator and machine.