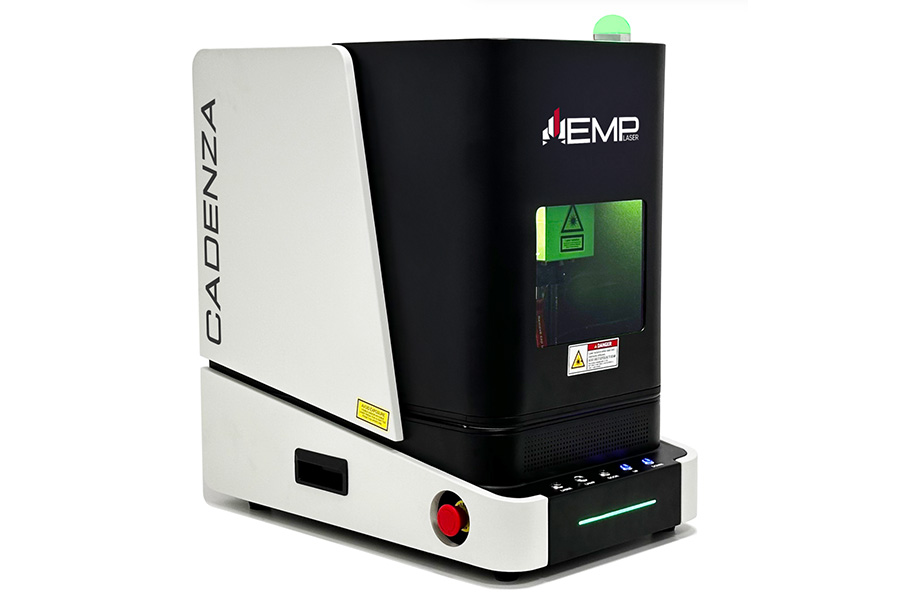

Blazing-Fast Marking

With cutting-edge MOPA and Galvanometric technology at its core, EMP laser markers achieve remarkable marking speeds that reduce cycle times. This makes the Cadenza an ideal choice for fast-paced production environments, from high-volume workshops to busy storefronts.

Cutting Power & Deep Engraves

With the right setup (60-100W), the EMP Cadenza can yield deep engravings and cut through thin metals using multiple passes, especially when paired with a vise to keep materials flat and distortion-free.

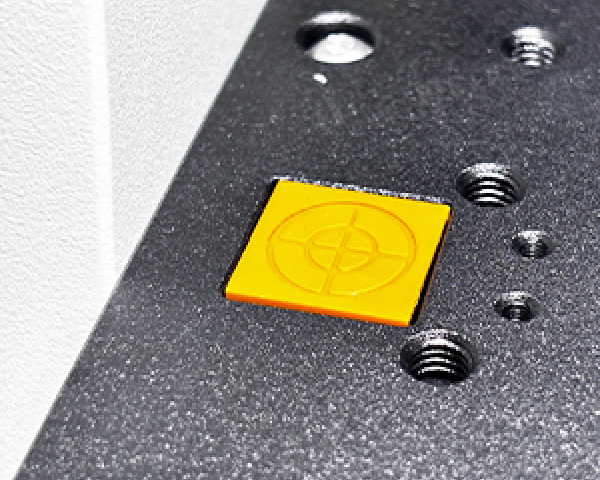

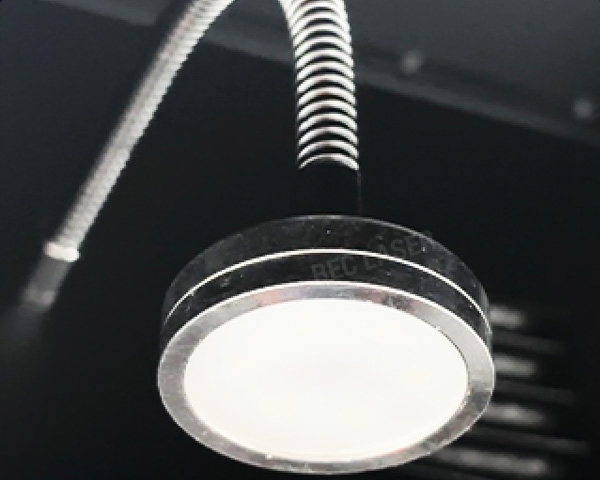

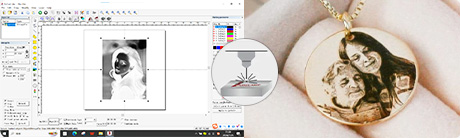

Exceptional Precision & Detail That Stands Out

The EMP Cadenza delivers razor-sharp accuracy, making it ideal for intricate artwork, photo-quality portraits, serial numbers, QR codes, barcodes, logos, and even micro-scale text. Its advanced technology ensures every mark is crisp and consistent, down to the finest detail.

Permanent and Resilient Marks

Engineered for durability, the EMP Cadenza produces engravings that resist fading, scratching, and wear. Whether on metal, plastic, ceramic, or other materials, each mark is permanent and ready to pass the test of time.

Extensive Material Compatibility

Stainless steel, aluminum (including anodized), brass, copper, titanium, gold, silver, platinum, nickel, chrome, carbon steel, cobalt alloys, tungsten, magnesium, ABS, polycarbonate (PC), polyethylene (PE), polypropylene (PP), polyamide (nylon), PEEK, PET, acrylic (PMMA), some ceramics, leatherette, painted or coated metals, epoxy resins, some composites and laminates, some rubbers.

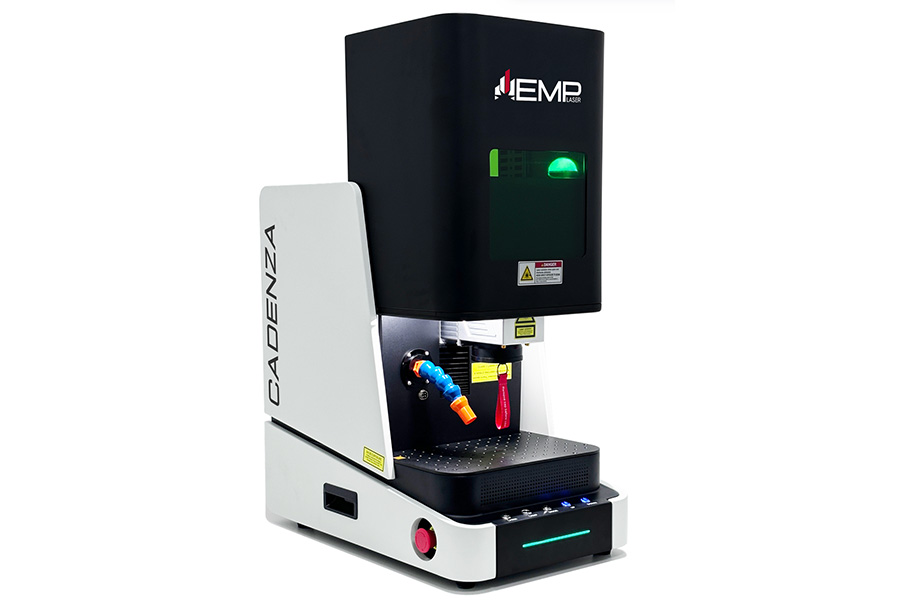

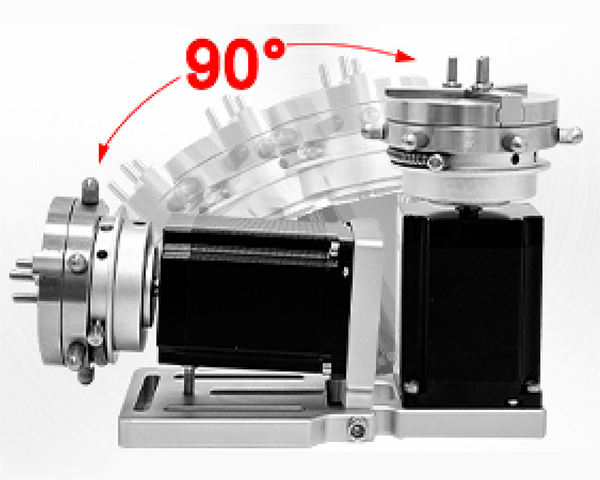

Engrave on Curved Surfaces

Effortlessly mark both the inside and outside of rings, bangles, and other small cylindrical items. The optional rotary chuck expands your capabilities, making engraving on curved surfaces fast, easy, and repeatable.

Compact Without Compromise

The Cadenza is built to fit comfortably into tight workspaces, offering powerful performance in a compact form. Whether on a workbench or in a small studio, it integrates effortlessly without sacrificing capability.

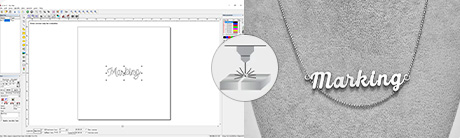

Simple, Streamlined Workflow

Featuring intuitive Lightburn software, setup and operation are fast and frustration-free. From intricate designs and batch processing to marking the inside or outside of rings, precision results are just a few clicks away.