Advantages of Using a CNC Laser Tube Cutting Machine

1 Unmatched Precision & Repeatability

Laser cutters provide unmatched precision and accuracy, enabling intricate cuts with clean, sharp edges that are difficult with traditional methods. The automated nature of laser cutting ensures consistent, repeatable results over time.

2 Tighter Tolerances

Laser tube cutters can achieve extremely tight tolerances, often as low as ±0.001 inches or more, ensuring high precision for critical applications. This level of accuracy is essential for industries requiring exact fit and finish, such as aerospace, automotive, and medical device manufacturing. Advanced CNC controls and rotary chuck systems enable consistent, repeatable cuts that meet stringent quality standards.

3 High-Speed Production

Fiber lasers cut up to 78 inches per second on thin tubes, dramatically reducing cycle times and increasing overall production efficiency. This high cutting speed allows manufacturers to complete jobs faster while maintaining precise, clean cuts. Additionally, the rapid processing capability helps reduce labor costs and improve throughput in high-volume tube processing operations.

4 Complex & 3D Cutting Capabilities

The programmable, multi-axis cutting head of a CNC laser machine can create intricate shapes and complex contours that are difficult to produce with conventional tools. Create slots, contours, miters, and 45° bevels directly with the laser — no grinding required.

These precise laser-cut features also enable a wide range of connections, such as bending connections and other jointing techniques, allowing for streamlined assembly without the need for welding or screws.

5 Material Versatility & Safety

Tube laser cutters can handle a wide range of materials; mild steel, stainless steel, aluminum, brass, copper and more. Laser cutting is a contactless process, preventing material contamination. This versatility allows for efficient processing of various metal types with minimal thermal distortion, ensuring high-quality cuts across different applications.

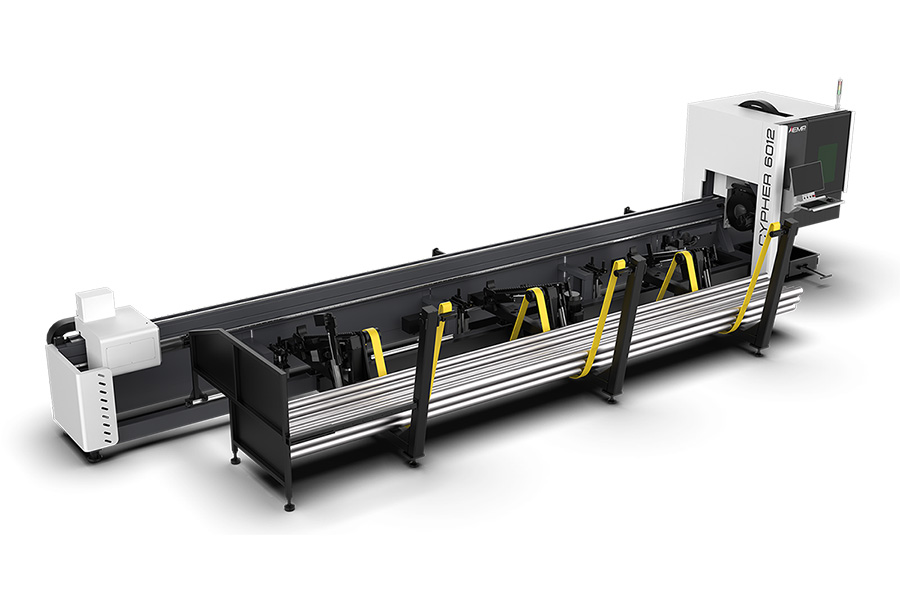

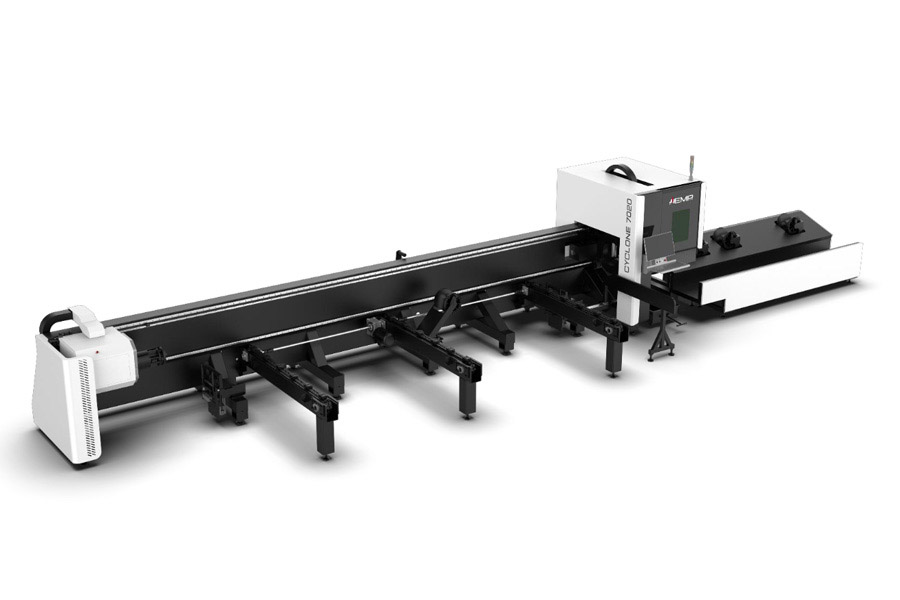

6 Automation & Labor Saving

Bundle loaders, part sorters, and CNC programming reduce manual handling and labor costs by automating material flow and production tasks. These features enable continuous operation with minimal human intervention, increasing throughput and overall efficiency. Automation also enhances safety by limiting operator exposure to moving parts and laser emissions.

7 Cleaner Cuts & Less Waste

The heat from laser cutting is highly focused, resulting in a much smaller heat-affected zone compared to other methods. This minimizes material warping, achieving higher quality results, more complex cuts, and less scrap. The narrow laser beam allows for more parts to be cut from a single tube, minimizing scrap and saving on material costs. The focused, non-contact thermal process of laser cutting also creates clean, burr-free edges and minimizes the need for post-processing.

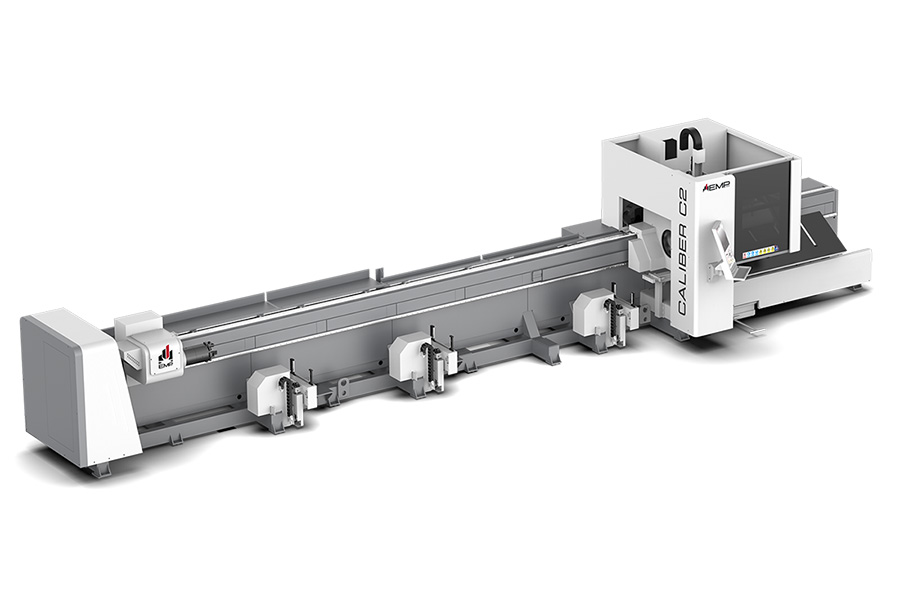

8 Streamline Production Steps

Advanced tube laser systems can perform multiple operations including cutting, notching, drilling, and marking in a continuous sequence, which streamlines production. This eliminates the need for manual repositioning or secondary processes, reducing setup time and labor costs. The result is faster production, greater precision, and consistent part quality across every job.

9 Workplace Safety

Modern fiber laser tube cutting machines are typically enclosed, reducing the risk of injury to operators by containing the laser beam and preventing accidental exposure. This enclosure also helps control fumes and debris generated during cutting, improving workplace safety and cleanliness. Additionally, safety interlocks and sensors are integrated to halt operation if the enclosure is opened, ensuring compliance with safety standards.

10 Lower Maintenance Costs Than Traditional Methods

While initial costs for laser tube cutting machines are higher, they can lead to long-term cost savings due to faster production, reduced waste, and less labor. Fiber laser machines often require less maintenance compared to traditional machines. There is no tool wear during laser cutting since it uses a beam of light rather than physical blades or bits. Laser cutting significantly reduces production time due to the high speed of the laser beam.