IPG Laser Source

The gold standard in laser performance, IPG sources deliver consistent power, exceptional cut quality, and unmatched reliability. Their robust design minimizes maintenance, ensuring uninterrupted operation even in the most demanding industrial environments.

MAX Laser Source

A smart, budget-friendly alternative, Max Photonics offers stable power output, excellent cut quality, and proven durability. It’s a dependable choice for operations that want efficiency and performance without the premium price tag.

Inovance Servo Motors

Inovance servo motors ensure fast response times and smooth motion control, ensuting percise cutting and engraving, even at high speeds. Their advanced feedback system enhances accuracy, while the durable, high-quality build guarantees long-term reliability. Engineered for seamless integration and optimal energy efficiency, they also maximize productivity while minimizing downtime.

Yaskawa Servo Motors

Yaskawa M7 series offers higher torque, faster response times, and enhanced stability, ensuring smooth, accurate motion control even at high cutting speeds. Its advanced algorithms minimize vibration and positioning errors, leading to cleaner cuts and improved machine efficiency. Built for durability and longevity, the M7 is an energy-efficient solution that maximizes performance while reducing operational costs.

Yaskawa Servo Motors

Yaskawa M7 series offers higher torque, faster response times, and enhanced stability, ensuring smooth, accurate motion control even at high cutting speeds. Its advanced algorithms minimize vibration and positioning errors, leading to cleaner cuts and improved machine efficiency. Built for durability and longevity, the M7 is an energy-efficient solution that maximizes performance while reducing operational costs.

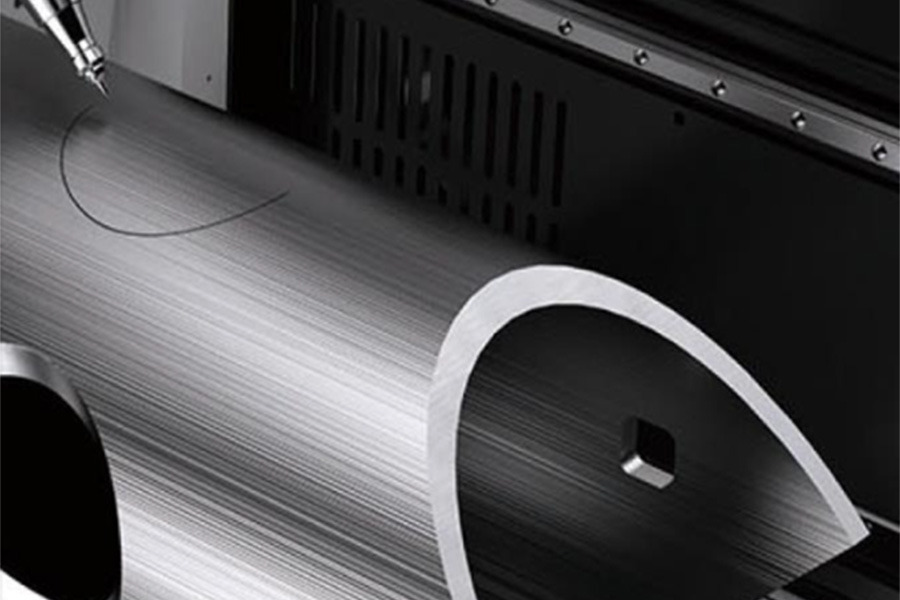

BOCI Laser Head

Boci laser heads are built for precision, efficiency, and durability, making them a standout choice for high-performance laser cutting. Featuring advanced autofocus, the BOCI head automatically adjusts cutting height for clean, consistent results across materials. Its breakaway design protects the head from collisions, reducing the risk of damage and downtime.

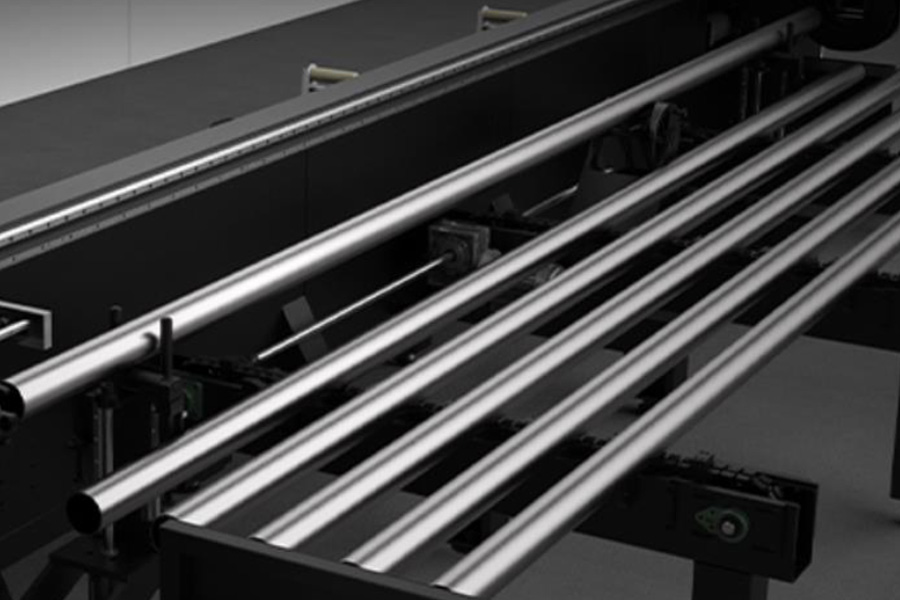

Hiwin Linear Guiderails YYC Rack and Pinions

This high-precision motion system combines Hiwin’s low-friction linear rails with YYC’s backlash-free rack and pinion for smooth, stable cutting. Built from high-quality materials, both deliver reliable accuracy and long-lasting durability, even under high-speed conditions.

Hiwin’s smooth, low-friction motion ensures accurate positioning and consistent performance, even at high speeds, while its rigid construction enhances longevity and reduces maintenance. Complementing this, YYC’s hardened rack and pinion system provides high-speed, backlash-free movement, ensuring clean, precise cuts with every pass. Built from high-quality materials, both components maximize efficiency, reliability, and cutting accuracy, making them essential for any precision-driven laser cutting operation.

S&A Water Chiller

S&A water chillers are engineered for efficient and reliable cooling, ensuring optimal performance. Designed with dual-circuit cooling, these chillers provide precise temperature control for both the laser source and optics, preventing overheating and maximizing efficiency. With intelligent temperature regulation, high energy efficiency, and a durable, low-maintenance design, the CWFL series keeps your laser running smoothly even under heavy workloads.

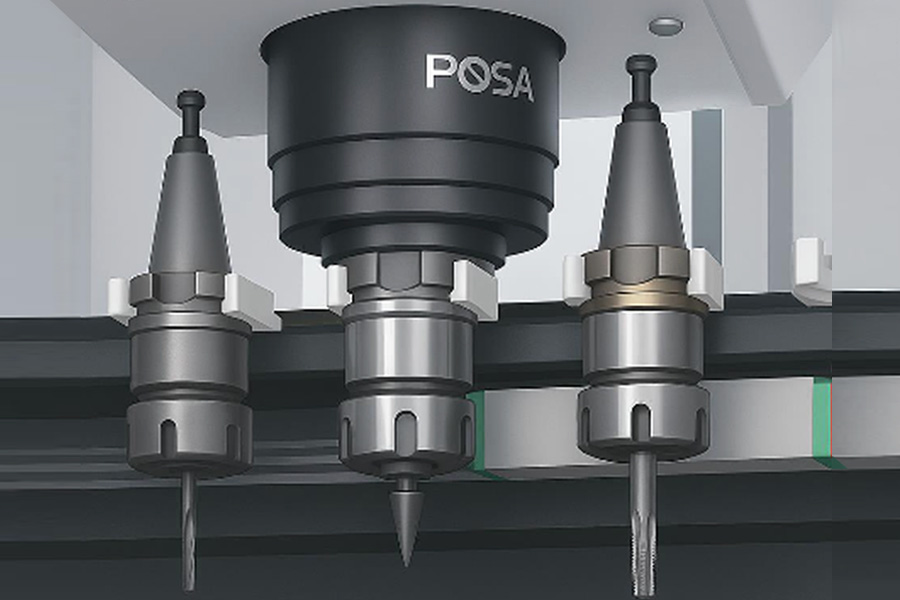

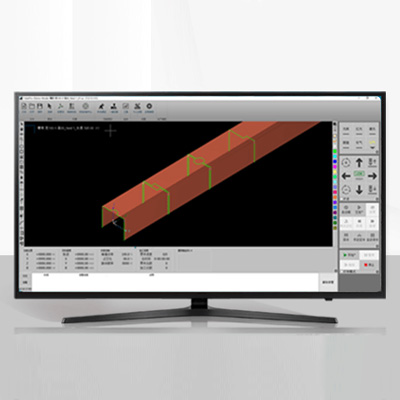

Bochu TubePro Software

Bochu TubePro is designed for professional tube cutting, and supports production of tube and profile of various shape. It works with Bochu TubesT nesting software seamlessly to realize technique setting, advanced toolpath generation and nesting for standard and special production need.