Choosing the Best Laser Cutting Machine Configuration

Choosing the right metal laser cutter configuration is key to maximizing efficiency, safety, and ROI. Whether you're a small workshop or a high-volume fabricator, there's a fiber laser metal cutting machine setup that fits your space, workflow, and production demands.

The 5 most common fiber laser cutter configurations

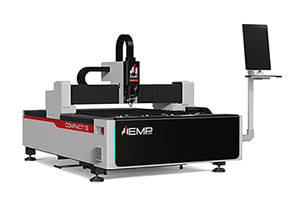

1. Open Fixed Bed Systems

An open bed laser cutter for metal is ideal for small shops, garages, or confined workspaces where floor space is limited and safety requirements are minimal. These compact machines are best suited for lower production volumes. For shops looking to boost throughput, an open bed fiber laser metal cutting machine can be upgraded with a dual-platform exchange table. While the laser cuts one sheet, a new sheet can be preloaded at the rear. When the cut is finished, the tables switch, allowing for continuous operation with minimal downtime.

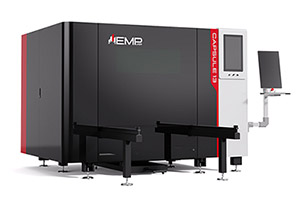

2. Enclosed Slide-Out Bed Systems

A fully enclosed CNC fiber laser cutting machine is the preferred option for established operations where foot traffic is higher and safety is a concern. These machines feature a safety enclosure and front-loading access via an electromagnetic pullout drawer. While they offer a relatively small footprint, loading and unloading must occur manually, and only while the machine is idle, making them better suited for medium-output environments where optimized production isn’t critical.

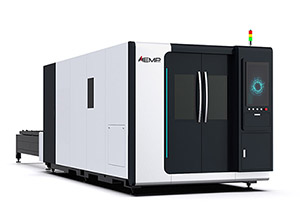

3. Enclosed Exchange Bed Systems

Combining safety and productivity, these systems feature a large-format enclosed bed with an exchange table. This configuration is popular in high-demand metal fabrication shops where throughput, automation, and workplace safety are top priorities. With optional auto loading and unloading systems, the fiber laser cutting machine can operate continuously without operator input, further maximizing output and minimizing labor.

4. Hybrid “Combo” Systems

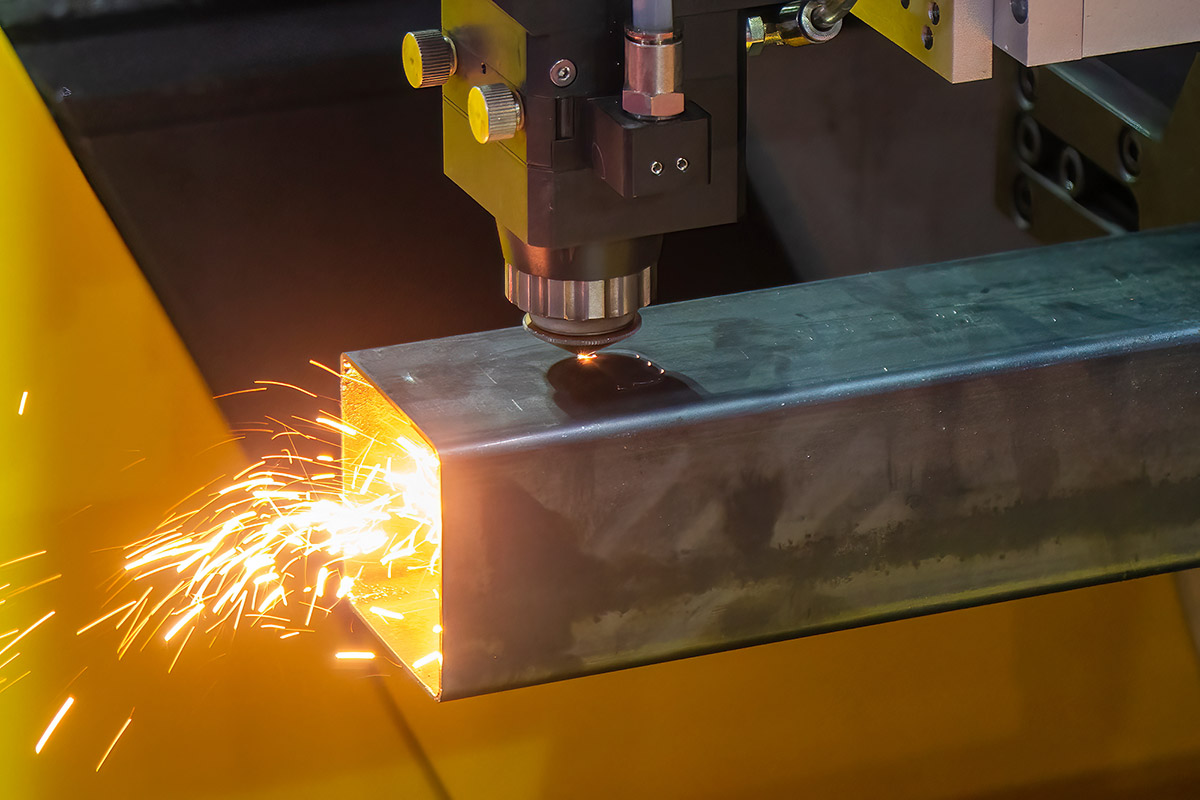

Combo lasers merge sheet cutting capabilities with rotary chucks for pipe and tube cutting. Whether paired with an open or enclosed bed, the fiber optic laser cutter includes an extended gantry that moves beyond the bed to process pipes or tubes mounted on the neighboring chuck. This hybrid setup is ideal for job shops handling diverse cutting jobs in both flat and cylindrical formats.

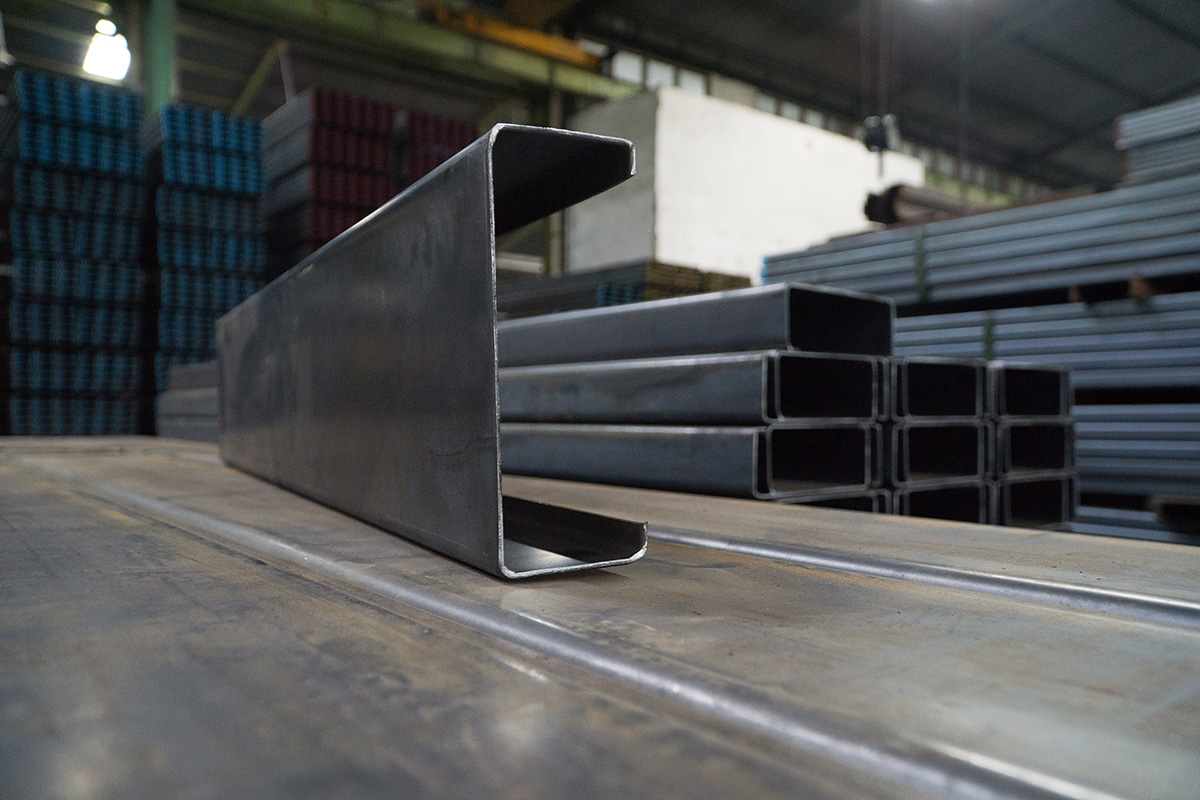

5. Dedicated Pipe/Tube Systems

For operations focused solely on tubular materials, a dedicated pipe and tube fiber laser metal cutting machine is the best choice. These systems come in various lengths and automation levels, and typically include enclosures and advanced safety features like laser fences to protect operators. Their design supports high-precision, high-volume pipe and tube fabrication of various profiles. Round, square, L, U and I beams can be cut in seconds with optional bevelling to support welding.

Fiber Laser Configurations

| Configuration |

Best For |

Loading |

Safety Level |

Automation Options |

Footprint |

| Open Fixed Bed |

Limited Space, Limited Budget |

Side (Front for small pieces) |

Low |

Exchange Table, Auto Load/Unload |

Small to Large |

| Enclosed Slide-Out Bed |

Limited Space, Safety Compliance |

Front Only |

High |

Manual Only |

Small to Large |

| Enclosed Exchange Bed |

Throughput, Safety Compliance |

Rear (Front for small pieces) |

High |

Auto Load/Unload |

Large to Extra Large |

| Open Fixed Bed Combo |

Versatility, Limited Space, Limited Budget |

Side (Front for small pieces) |

Low |

Exchange Table, Auto Load/Unload |

Large to Extra Large |

| Enclosed Exchange Bed Combo |

Versatility, Throughput, Safety Compliance |

Rear for Sheet, Side for Tube (Front for small pieces) |

Med |

Auto Load/Unload |

Large to Extra Large |

| Dedicated Pipe/Tube |

Throughput |

Side Only |

Med |

Auto Load/Unload |

Large to Extra Large |