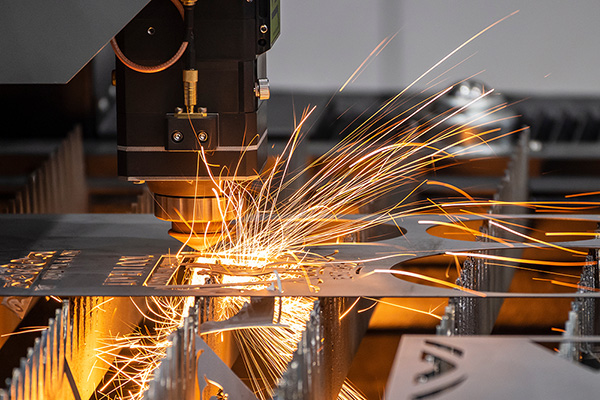

Traditional cutting methods struggle to meet evolving requirements, often resulting in slower production times, higher operating costs, and quality inconsistencies that impact downstream manufacturing processes.

Fiber laser steel cutting represents a leap forward in metal fabrication technology, delivering cutting speeds 3-5 times faster than conventional methods while maintaining superior edge quality and dramatically reducing operational costs.

Talk to Our Team

Fiber laser technology uses a special kind of laser made from an optical fiber that contains rare elements like ytterbium. Unlike other lasers, fiber lasers produce a very focused and powerful beam of light at a wavelength that steel and other metals absorb very well.

The cutting starts when electricity powers small laser diodes that excite the fiber, creating a strong laser beam. This beam is so powerful that it can quickly melt or vaporize steel right where it is focused.

Because the laser beam is very precise and intense, it can cut through metal with great accuracy and speed. This makes fiber lasers an ideal choice for cutting steel and other metal alloys cleanly, including mild steel and galvanized steel, without causing much damage to the surrounding material. The process is capable of handling varying thicknesses of sheet metal, including thick steel, and produces clean edges with minimal heat distortion.

This efficient cutting process generally results in low cost operations and is perfect for mass production where high quantity and consistent quality are essential. Fiber laser steel cutting is also effective for cutting aluminum and other metals, making it a versatile solution in sheet metal fabrication.

The fundamental design of fiber laser systems provides several technical advantages over traditional cutting methods:

| Specification | Fiber Laser | CO2 Laser | Plasma Cutting |

|---|---|---|---|

| Electro-optical efficiency | 25-35% | 8-10% | N/A |

| Beam delivery | Fiber optic | Mirror system | Plasma arc |

| Maintenance requirements | Minimal | High | Moderate |

| Cutting speed (thin steel) | 3-5x faster | Baseline | Slower |

| Edge quality | Burr-free | Good | Requires finishing |

This efficiency translates directly into lower electricity consumption, reduced heat generation, and simplified maintenance requirements that significantly impact long-term operational costs.

Fiber lasers boast a longer service life compared to traditional laser sources, often exceeding 100,000 hours of operation, which further reduces replacement frequency and downtime.

The compact design of fiber laser systems also allows for easier integration into existing manufacturing lines, saving valuable floor space and enabling more flexible production setups.

The high beam quality and stability of fiber lasers ensure consistent cutting performance over time, minimizing variability and enhancing overall product quality.

These factors combined make fiber laser steel cutting not only a powerful technological advancement but also a financially sound investment for manufacturers aiming to optimize their production efficiency and cost-effectiveness in the long run.

Using fiber laser cutters for cutting steel greatly improves productivity thanks to its advanced laser beam and optimized cutting settings. Modern fiber laser systems can cut sheet metal at high speeds for thin materials. The cutting feed rate automatically adjusts depending on the material’s thickness and type, ensuring efficient and precise cutting every time.

The cutting process operates through two primary mechanisms: fusion cutting and sublimation cutting.

In fusion cutting, the laser melts the steel while high-pressure assist gas pressure expels molten material, producing clean, burr-free edges. Fusion cutting is the most common method used for thicker metals, where the assist gas, often nitrogen or oxygen, plays a critical role in blowing away molten metal and preventing oxidation or enhancing the cutting speed.

Sublimation cutting uses direct vaporization of material for extremely thin or delicate applications. It is ideal for very thin metals or specialized applications where minimal thermal impact is essential to preserve the material's properties and prevent warping.

These mechanisms are carefully controlled by adjusting parameters such as laser power, cutting speed, and gas type to optimize performance for different materials and thicknesses.

Accurate cutting capabilities distinguish fiber laser systems from conventional methods. These machines typically achieve exceptional position accuracy, tigher tolerances, smoother edges, and minimal heat-affected zones.

Positional accuracy within ±0.05 mm per 10 mm of material thickness

Surface roughness of Ra 3.2-6.3μm on cut edges

Heat-affected zones less than 0.1 mm

Perpendicularity tolerances maintaining precise dimensional control

Modern fiber laser systems integrate advanced sensor technologies and real-time monitoring to continuously adjust the cutting nozzle parameters and maintain optimal focus and gas flow throughout the process. This dynamic control helps minimize defects such as dross formation, heat distortion, and uneven edges, ensuring consistently high-quality results even in complex or high-volume production runs.

The precision of the laser beam combined with automated CNC controls enables intricate designs and tight tolerances that are difficult to achieve with traditional mechanical cutting tools. The focused beam diameter can be reduced to as small as 0.01 mm, enabling intricate geometries and tight nesting patterns that maximize material utilization while maintaining top notch cut quality. This makes fiber laser steel cutting highly suitable for industries where exact dimensions and surface finish are critical, such as aerospace, medical devices, and automotive manufacturing.

The choice of assist gas significantly influences the quality and characteristics of the cut. The benefits of each gas are listed below.

Gas |

Use |

|---|---|

Nitrogen |

Typically used for achieving oxide-free, bright edges, making it suitable for applications requiring subsequent welding or coating. |

Oxygen |

Can increase cutting speed on mild steel by promoting an exothermic reaction, but it may leave a slight oxide layer on the edges. |

Compressed air |

Offers a cost-effective alternative for general-purpose cutting but may not provide the same edge quality as inert gases. |

Learn more about Assist Gas Selection and Performance

Operating costs for fiber laser systems typically range from $5-25 per hour, representing potential savings of 50-70% compared to traditional cutting methods.

This low cost operation stems from:

Higher electrical efficiency reducing power consumption

Simplified beam delivery eliminating mirror alignment and maintenance

Longer laser source life spans (100,000+ hours)

Reduced consumable requirements

The maintenance advantages greatly reduces downtime and associated labor costs, making fiber laser technology an ideal choice for high-volume production environments.

In addition to reducing downtime, fiber laser systems require less frequent calibration and alignment compared to traditional laser cutters. This is largely due to the solid-state nature of the fiber laser source, which is more stable and less prone to misalignment from vibrations or thermal fluctuations. Consequently, maintenance intervals are extended, reducing the need for costly service visits and minimizing disruptions to production schedules.

Another significant benefit is the reduced wear on consumable parts. The precision and consistency of the laser beam minimize damage to focusing lenses and cutting nozzles, prolonging their lifespan. This not only lowers replacement costs but also ensures consistent cut quality over extended production runs.

Fiber laser systems often feature automated diagnostics and self-monitoring capabilities. These smart features can detect potential issues early, alerting operators before a problem causes downtime or quality defects. This proactive maintenance approach helps maintain optimal machine performance and further enhances overall operational efficiency.

Overall, the combination of low maintenance requirements, durable components, and intelligent monitoring makes fiber laser technology particularly well-suited for demanding industrial environments where reliability and uptime are critical. This translates into greater productivity, lower total cost of ownership, and improved profitability for manufacturers utilizing fiber laser steel cutting.

In summary, the cutting process in laser cutting machines is a sophisticated interplay of laser energy, assist gas, and precise mechanical control, delivering exceptional efficiency and quality across a broad range of metal fabrication applications.

Understanding the step-by-step cutting process helps optimize operations and achieve consistent results across varying thicknesses and material types.

Sheet metal fabrication begins with proper material positioning on the cutting table. Modern laser cutting machines feature automated material handling systems that ensure precise alignment and reduce setup time for mass production runs.

An important feature called Edge Seek allows the laser head to scan for the edges of the metal sheet, enabling the system to detect and orient the job correctly even if the sheet is not placed perfectly square in the laser bed. This capability improves accuracy and reduces material waste by compensating for slight misalignments during setup.

The laser source generates a coherent light beam that travels through the optical fiber to the cutting head. Advanced focusing optics concentrate this energy at the focal point, creating the intense energy density required for efficient metal cutting.

The laser head is equipped with an automatic height adjustment system that continuously monitors and maintains a precise distance between the cutting nozzle and the material surface. This ensures the laser beam remains perfectly focused across the entire cutting bed, compensating for any material warping, thickness variations, or surface irregularities, thereby guaranteeing consistent cut quality throughout the job.

Most auto focus laser heads include an intelligent scanning feature that detects any sections of the cut metal that may have lifted or tipped upward and could potentially interfere with the laser head. In response, the laser head quickly elevates to avoid contact, thereby protecting both the integrity of the material and the precision equipment from damage.

When the focused beam contacts the steel surface, rapid heating occurs at the interaction point. The cutting nozzle delivers assist gas under controlled gas pressure to remove molten material and prevent oxidation of cut lines.

Air assist or specialized gases like nitrogen create clean edges while maintaining the narrow kerf width that characterizes precise cuts. The choice of assist gas affects both cutting speed and final edge quality. Additionally, the assist gas protects the laser optics by preventing debris buildup on the lens.

Proper gas pressure is crucial—too low can cause rough edges, while too high may widen the kerf or deform the material. Modern laser cutting machines use adjustable nozzles to maintain optimal gas flow, ensuring consistent, high-quality cuts across different materials and thicknesses.

Computer Numerical Control (CNC) systems guide the cutting head along programmed paths with exceptional precision. This automation ensures repeatability and enables complex geometries while maintaining consistent quality across production runs.

At its core, the CNC system interprets 2D CAD drawings by plotting a precise course that follows the paths and contours defined in the design. This ensures the laser cutter moves exactly according to the specified outlines, holes, and cut lines, faithfully reproducing the intended shapes on the sheet metal.

The CNC software allows operators to sort and optimize the order in which different elements of the drawing are cut. By strategically sequencing the cuts, the system minimizes unnecessary head movement, reduces cutting time, and prevents potential thermal distortion or material shifting, thereby enhancing overall efficiency and cut quality.

CNC control supports the nesting of multiple parts on a single sheet, maximizing the surface area utilization of the sheet metal and minimizing scrap. This capability is particularly valuable in mass production environments where efficiency and material costs are critical.

The software interface used to program CNC systems often includes simulation tools that visualize the cutting path and predict potential issues before actual cutting begins. This preemptive analysis helps avoid costly mistakes and ensures the highest possible cut quality.

Fiber laser technology excels with a wide range of steel types and alloys, making it versatile for diverse manufacturing applications. Its adaptability allows it to efficiently cut through various grades and compositions, ensuring consistent performance regardless of material complexity.

One of the key strengths of fiber lasers is their ability to handle both ferrous and non-ferrous metals with precision. This includes not only common steels but also specialty alloys used in aerospace, automotive, and medical industries. The technology's fine control over beam intensity and focus enables clean cuts even on reflective or hard-to-machine materials, reducing the need for secondary finishing processes.

Fiber laser systems can be customized with different power levels and cutting heads to optimize performance for specific materials and thicknesses. This flexibility supports a broad spectrum of applications, from delicate thin-gauge sheet metal to thick structural components, all while maintaining high throughput and minimal thermal distortion.

In addition to steel and its alloys, fiber laser technology is effective in cutting other metals such as aluminum, copper, brass, titanium, and nickel alloys. This multi-material capability makes fiber lasers a valuable asset for fabrication shops that require versatility without compromising on speed or quality.

Overall, the broad material compatibility and precise control offered by fiber laser technology make it an indispensable tool in modern metal fabrication, capable of meeting the demanding standards of today's manufacturing landscape.

Fiber laser cutting technology can handle a variety of metals with ease.

Material |

Benefit of Fiber Cutting |

Uses |

|---|---|---|

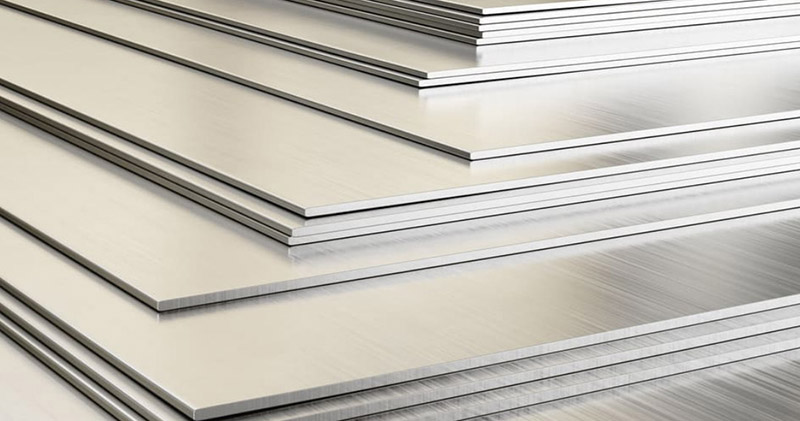

Mild steel (Low-carbon steel) |

Cuts smoothly and accurately up to 40mm thick. Fast and cost-effective. |

structural applications |

Stainless steel (304,316,409,430) |

Delivers clean edges and oxide-free finish |

Hygienic equipment, such as food-grade and medical uses |

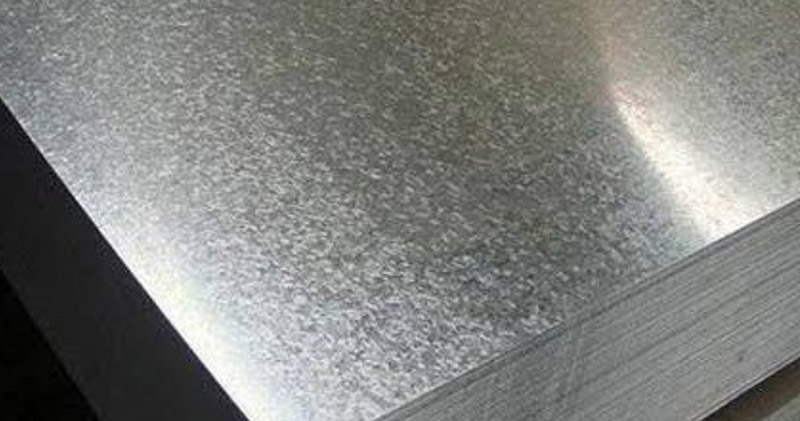

Galvanized steel |

Cuts cleanly while protecting the coating, making it great for corrosion-resistant projects |

|

Tool steel (D2, A2, O1) |

Offers precise cuts |

Knives, dies, molds, and industrial tooling |

High-strength alloys |

Keeps edge quality even with tougher steels |

HVAC, enclosures, and coated sheet projects |

Modern fiber laser systems are designed to expertly handle varying thicknesses of materials by fine-tuning cutting parameters for each specific job.

Material Thickness |

Methodology |

|---|---|

|

Thin materials (0.5-3mm) |

The focus is on maximizing speed and cutting efficiency without compromising quality. |

|

Medium thickness (3-15mm) |

The system strikes an optimal balance between speed and precision, ensuring clean, accurate cuts. |

|

Thick steel (15-100mm) |

The feed rate is adjusted to a slower pace to maintain consistent precision and edge quality throughout the cut. |

If you know the material type and thickness you need to cut, see our Fiber Laser Cutting Process Parameter charts for more info:

See how much laser power you need to cut steel

This adaptability allows fiber laser technology to be highly effective across a broad range of applications, from delicate sheet metal components to robust structural elements, making it a versatile solution for modern metal fabrication needs.

Gas selection significantly impacts cutting performance. Choosing the right assist gas is crucial for optimizing the cutting process and achieving the desired cut quality.

Nitrogen is often preferred when a clean, bright edge is necessary, especially if the parts will undergo further processing such as welding or painting. Its inert nature prevents oxidation, resulting in smooth, high-quality edges that require minimal finishing.

Oxygen, on the other hand, acts as a reactive gas that supports an exothermic reaction during cutting, which can significantly increase the speed of cutting mild steel. However, this comes at the expense of leaving a thin oxide layer on the cut edge, which might require additional cleaning or finishing depending on the application.

Compressed air offers a practical balance between performance and cost, making it a popular choice for general fabrication tasks where extreme edge quality is less critical. It provides sufficient gas pressure to clear molten material while being more economical than pure nitrogen or oxygen.

Advanced laser cutting machines often include programmable gas control systems that allow operators to switch between gases or adjust gas pressure dynamically during a job, optimizing performance for complex parts with varying thicknesses or material types. Proper gas flow and pressure settings are essential to prevent common issues such as dross buildup, kerf widening, or heat distortion, all of which can negatively impact the final product quality.

In summary, understanding the properties and effects of different assist gases helps manufacturers tailor their fiber laser steel cutting operations to balance speed, quality, and cost effectively.

Laser cutting machines are available in several configurations to match different production requirements.

System |

Material range |

Investment |

Best For |

|---|---|---|---|

|

Entry-Level Systems (800W - 1.5 kW) |

0.5-6mm steel |

$30,000-$90,000 |

Prototyping and low volume production |

|

Professional Systems (3-6 kW) |

0.5-25mm steel |

$100,000-$250,000 |

General fabrication shops |

|

Industrial Systems (12-60 kW) |

Up to 40mm steel |

$200,000-$750,000 |

High end productivity for mass production |

Most manufacturers report payback periods between 2-4 years, with some achieving ROI in as little as 18 months.

The financial benefits include:

Increased throughput enabling higher revenue per machine

Reduced labor costs through automation

Lower material waste due to optimized nesting

Quality improvements reducing rework and scrap

For example, a medium-sized fabrication shop processing aluminum, stainless, and mild steel components reported 60% faster production times and 40% reduction in finishing operations after implementing fiber laser technology.

| Model |

Nano |

Compact |

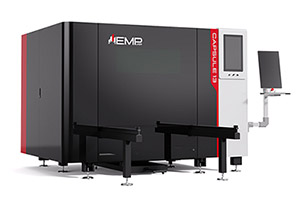

Capsule |

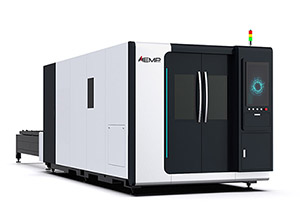

Command |

Crossover |

|---|---|---|---|---|---|

| Power Options | 0.8-1.5kW | 1.5-6kW | 1.5-6kW | 6-40kW | 6-40kW |

| Work Area | 7.87” x 11.81” (20x30cm) |

3’ x 3’ (60x60cm) 4’ x 4’ (1.3x1.3m) 5’ x 10’ (1.5x3m) |

3’ x 3’ (60x60cm) 4’ x 4’ (1.3x1.3m) 5’ x 10’ (1.5x3m) |

5’ x 10’ (1.5x3m) 6.5’ x 13’ (2x4m) 6.5’ x 20’ (2x6m) |

5’ x 10’ (1.5x3m) 6.5’ x 13’ (2x4m) 5’ x 20’ (1.5x6m) |

| Bed Configuration | Enclosed Clamp-Vice | Open Fixed Bed | Enclosed Slide-Out Bed | Enclosed Exchange Bed | Enclosed Exchange Bed Combo |

| Best For | Confined Spaces, Jewelers, Limited Budget | Limited Space, Limited Budget | Limited Space, Safety Compliance | Throughput, Safety Compliance | Versatility, Throughput, Safety Compliance |

| Starting At | $32,450 | $58,950 | $73,950 | $128,950 | $198,950 |

| Learn More | Nano | Compact | Capsule | Command | Crossover |

Precision cutting of chassis components, brackets, and structural elements benefits from the clean edges and dimensional accuracy that fiber laser technology provides. Manufacturers report significant improvements in welding quality due to superior edge preparation.

The minimal heat distortion and precise edge quality make fiber laser cutting essential for medical device components where dimensional accuracy and surface cleanliness are critical for patient safety and device performance.

Sheet metal fabrication for building components, aluminum panels, and structural elements benefits from the speed and precision of modern laser technology. The ability to process thick materials while maintaining edge quality streamlines construction workflows.

Job shops processing diverse materials from copper and brass to titanium and nickel alloys find fiber laser systems provide the versatility needed for custom work while maintaining production efficiency.

The fiber laser cutting industry continues advancing through several key developments:

Systems exceeding 20 kW enable single-pass cutting of extremely thick materials

AI-driven optimization of cutting parameters and predictive maintenance

Integration with bending, welding, and other fabrication processes

Cloud-based monitoring and remote diagnostics

These advances position fiber laser steel cutting at the forefront of modern manufacturing, offering capabilities that continue expanding the possibilities for precision metal fabrication.

As your strategic sourcing partner, we simplify the complexity of acquiring high-performance metal fabrication equipment by offering end-to-end services and solutions designed around your real-world needs.

We handpick the best equipment from trusted global manufacturers—no brand bias.

Get tailored advice to match your workflow, goals, and budget.

We handle freight and customs so your machines arrive hassle-free.

Professional setup ensures your equipment is ready to perform on day one.

We train your team for safe, efficient, and confident machine operation.

Choose ongoing maintenance plans that keep your shop running smoothly.

We rigorously test and vet every machine before it reaches your floor.

We help you scale smart with the right tools at the right time.

Need something unique? We help design and deliver custom fabrication systems.

Fiber laser steel cutting represents a fundamental shift in metal fabrication capabilities, delivering the combination of speed, precision, and cost-effectiveness that modern manufacturing demands. The technology’s superior electrical efficiency, minimal maintenance requirements, and exceptional edge quality make it an ideal choice for fabricators seeking competitive advantages.

Whether processing thin sheet metal for precision components or handling thick structural elements, fiber laser systems provide the versatility and performance needed to meet diverse production requirements. The proven ROI and expanding capabilities of this technology make it an essential consideration for any fabrication operation focused on quality, efficiency, and profitability.

As the technology continues evolving with higher power levels and enhanced automation features, fiber laser steel cutting will play an increasingly central role in defining the future of metal fabrication across industries ranging from automotive and medical devices to construction and general manufacturing.

Whether you're cutting your first sheet or scaling up to industrial production, EMP Laser delivers precision, performance, and support every step of the way.

Talk to Our Team