Whether you're looking to mark metals, engrave detailed text, or scale up production, EMP Laser's fiber laser marking machines and UV lasers are engineered for speed, accuracy, and industrial reliability.

Explore our range of UV, MOPA, and Galvo fiber laser systems for every marking need.

Get a Quote View Machine Specs

From high-speed metal engraving to precision plastic and color marking, this comparison helps you choose the right fiber, MOPA, UV, or galvo laser system for your materials, applications, and production needs.

Laser Type |

Fiber Laser Engraver |

MOPA Fiber Laser |

UV Laser |

Galvo Laser Marker |

|---|---|---|---|---|

|

Best For |

Engraving and marking on metals (steel, aluminum, brass, copper), and hard plastics |

Color marking on stainless steel and highly detailed plastic engraving |

Heat-sensitive materials like plastic films, silicone, rubber, glass, and ceramics |

Uses galvanometer mirrors to move the laser beam at incredible speeds |

|

Advantages |

Zero consumables, fast, long lifespan, consistent depth and clarity |

Color marking on stainless steel and highly detailed plastic engraving |

Operates at 355nm wavelength = cold marking with almost no heat damage, ultra-fine detail |

Marking speeds 5-10x faster than gantry lasers, ideal for mass production |

|

Applications |

Industrial tools, machine parts, serial numbers, traceability codes |

Adjustable pulse width for precise control over contrast and color, ideal for branding and detailed work |

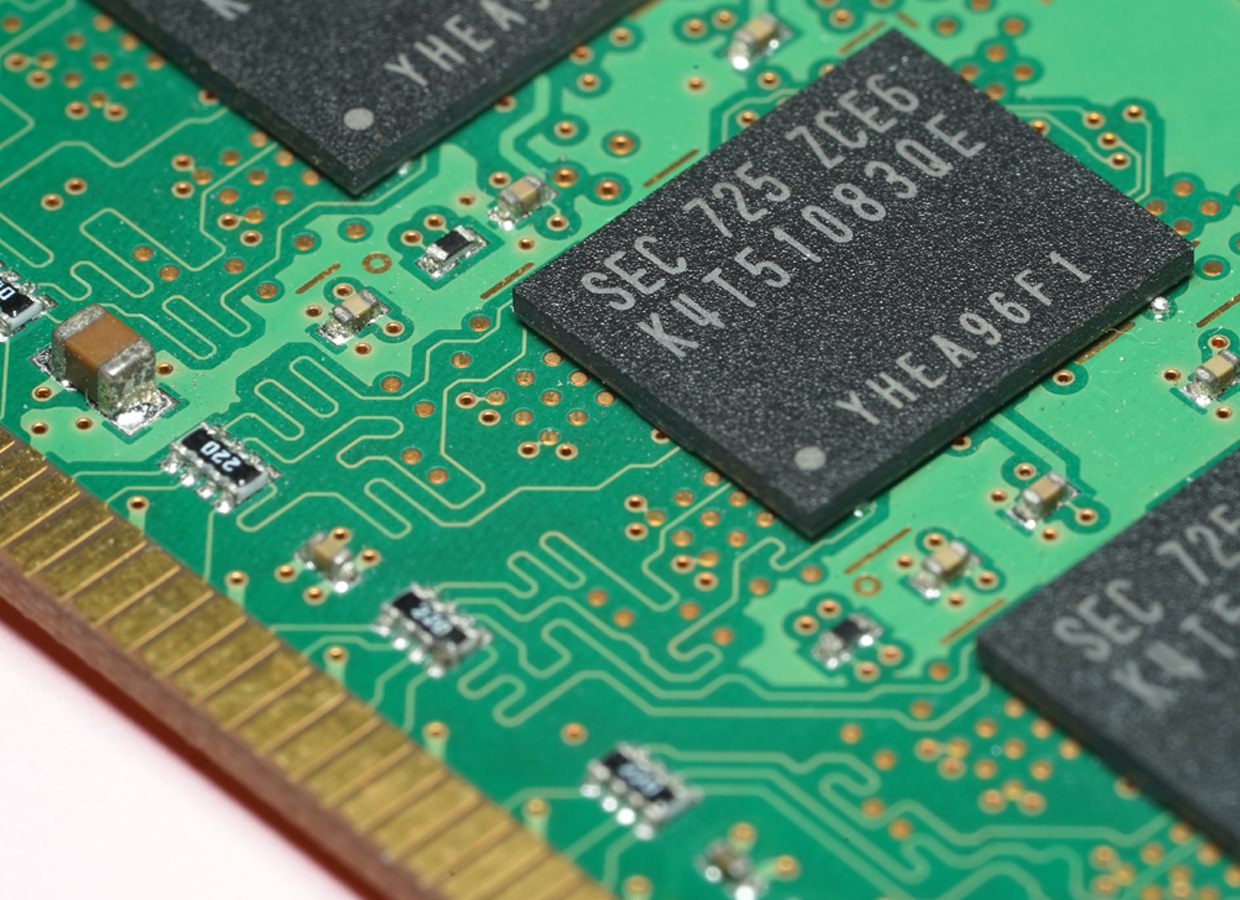

Circuit boards, pharmaceutical packaging, lenses, ID cards |

Batch coding, serialized marking, product traceability, promotional products, name tags |

A fiber laser marking machine is an industrial tool used to permanently mark or engrave materials—especially metals and certain plastics—using a focused laser beam. These machines use fiber optic technology to deliver a high-intensity laser beam with a wavelength of 1064 nanometers, ideal for precise, high-contrast results.

Require no consumables or refills

Offers lifespan over 100,000 hours

Operate with virtually no maintenance

Deliver micron-level precision even at high speeds

Fiber lasers are particularly effective for applications requiring durability and legibility—like barcodes, serial numbers, QR codes, and permanent marking on metal parts. They’re the go-to solution for industries such as aerospace, automotive, medical devices, electronics, and tooling.

Fiber laser marking machines are known for their low maintenance costs and high reliability.

The net weight of some fiber laser marking machines can be around 120 lbs. This makes them portable and easy to move.

Users appreciate the ease of use of fiber laser marking machines, which often operate like a printer driver.

Fiber laser marking machines can be easily integrated with existing production lines for automation.

Fiber laser marking machines typically have a long operational lifetime of around 100,000 hours.

Because of their power, speed, and low running cost, fiber laser markers are a smart long-term investment for manufacturers who need reliable, scalable marking systems.

|

Laser Type |

EMP Galvo Fiber Marker |

EMP MOPA Fiber Marker |

EMP Galvo UV Marker |

EMP Cadenza Fiber Marker |

|---|---|---|---|---|

|

Model |

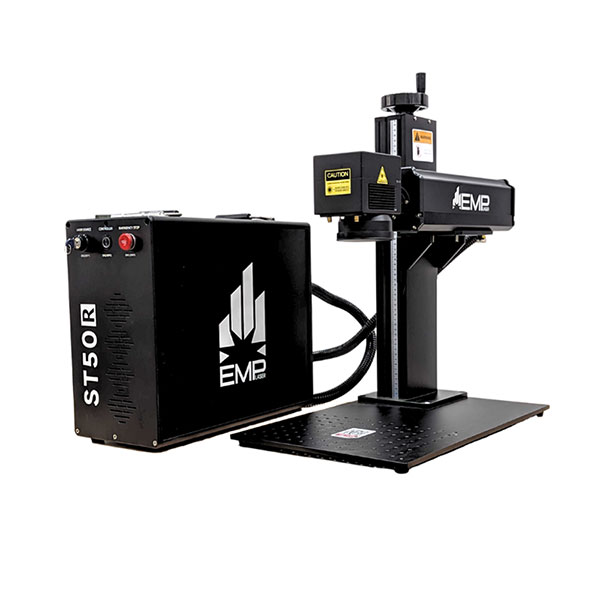

EMP ST30R, EMP ST50R |

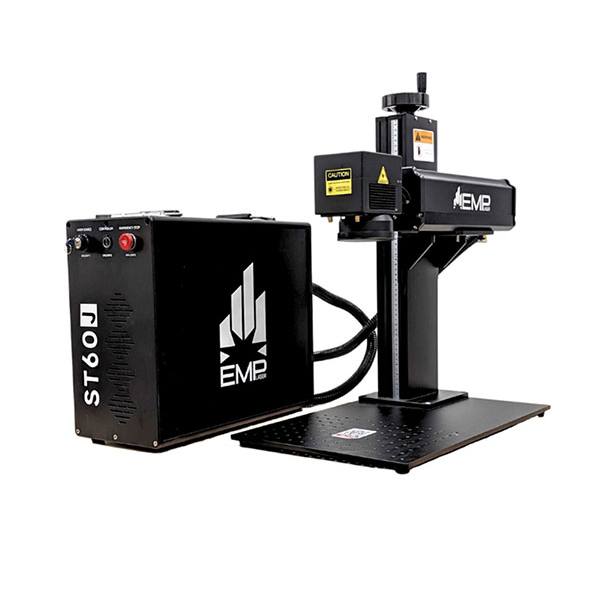

EMP ST60J, EMP ST100J |

ST5J, ST10J, ST15J |

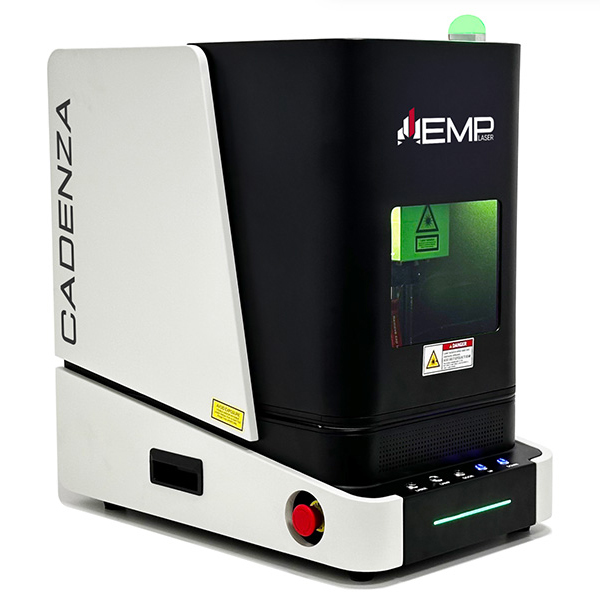

Cadenza |

|

Power Options |

30W Raycus, 50W Raycus |

60W MOPA, 100W MOPA |

5W UV, 10W UV, 15W UV |

JPT M7 30W, JPT M7 60W, JPT M7 100W, JPT M7 200W |

|

Marking Area |

200mm x 200mm (7.87" x 7.87") default, up to 300mmx300mm (11.8"x11.8") |

200mm x 200mm (7.87" x 7.87") default, up to 300mmx300mm (11.8"x11.8") |

4.3" x 4.3" (110mm x 110mm), 5.5" x 5.5" |

4.3" x 4.3" (110mm x 110mm) |

|

Features |

Entry-level fiber laser for metals and plastics. Mid-range production model with high throughput |

For color marking, plastics, and delicate detail |

For micro-marking on heat-sensitive materials |

Industrial-grade precision in a compact form. Enclosed. |

|

Compatible Materials |

Metals: |

Metals: |

Acrylic, Glass, Ceramics, Stone, Metal (coated, anodized, or bare), Silicone, Leather, Rubber, Wood, Paper, Certain Plastics (like PEEK) |

Metals: |

|

Starting At |

$4995 |

$8995 |

$8995 |

$14,995 |

|

Learn More |

Talk to a Product Specialist

It's easier to enter the world of laser marking with EMP by your side—even for those new to the technology, we provide expert consulting and resources to ensure your machine is fully operational from day one.

Industrial-Grade Reliability

U.S.-Based Customer Support

Easy Setup & Exclusive Features

Compatible Software

EMP Laser machines are built to serve a wide range of industries with uncompromising reliability.

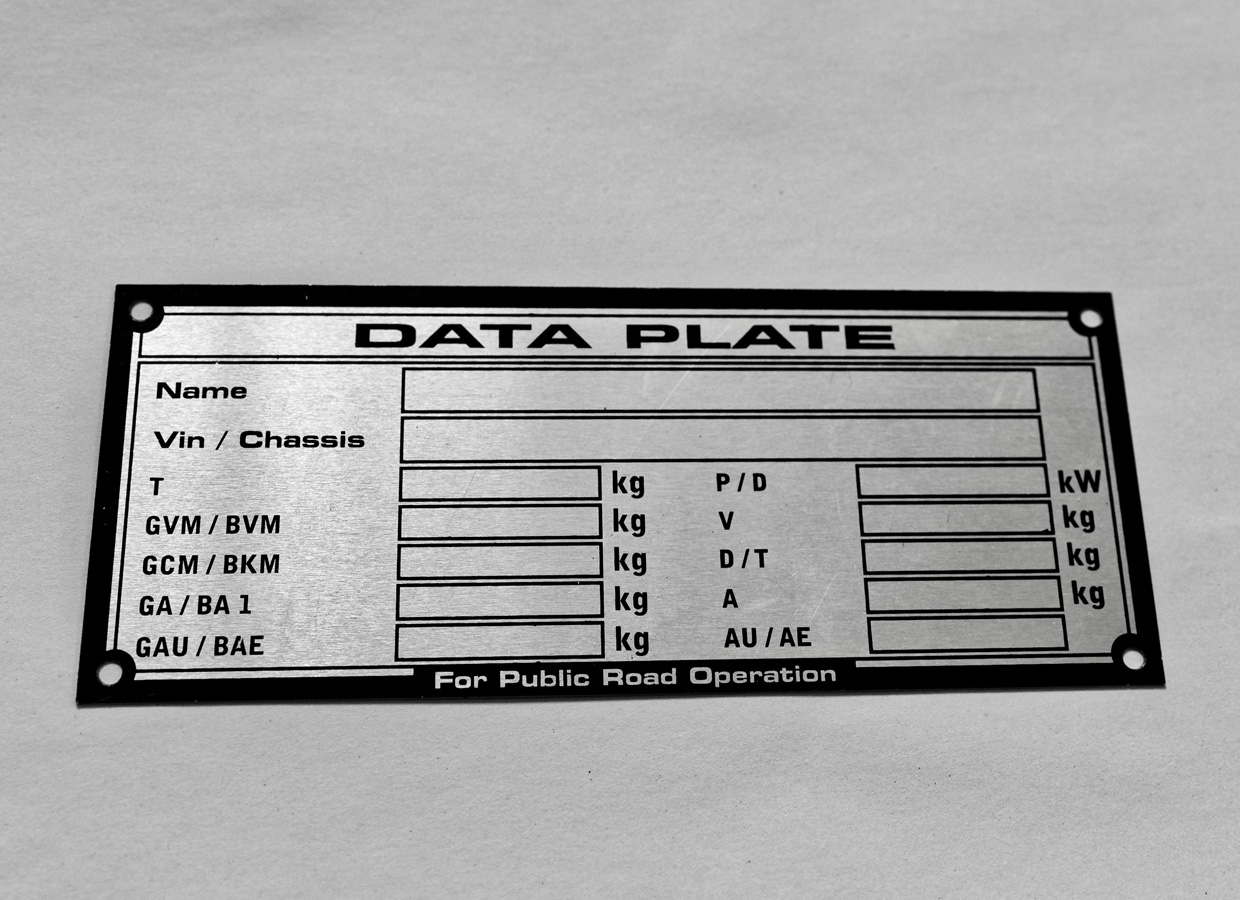

Marking durable VIN numbers, Engrave serial numbers, part IDs, and QR codes on aluminum, steel, or titanium parts. Fiber lasers meet strict traceability and compliance standards (ISO, UID, AS9100).

UV and MOPA lasers are ideal for labeling microchips, PCBs, sensors, and connectors. Delicate materials stay intact thanks to ultra-low heat.

Fiber laser markers deliver clean, permanent identification on surgical tools, instruments, and implants. MOPA fiber lasers enable high-contrast UDI codes and branding on stainless steel while preserving surface integrity—supporting sterilization requirements, traceability, and regulatory compliance.

Fiber laser markers enable precise branding, decorative detailing, and personalized engraving on fine jewelry and accessories. MOPA fiber lasers are especially well-suited for color marking and ultra-fine detail on rings, watches, pendants, and luxury gift items, delivering high-end results without compromising material integrity.

Name Tags & Employee Badges – Permanent, wear-resistant marking on stainless steel or anodized aluminum

Identification & Access Tags – Serialized or barcode-marked tags for security, access control, and compliance

Asset Tags & Inventory Labels – Durable QR codes and serial numbers for equipment tracking

Hospitality Signage – High-end signage, room numbers, and wayfinding plaques for hotels and venues

Awards & Recognition Plates – Clean, professional engraving for plaques, trophies, and commemorative items

Corporate Branding Elements – Logos and branded plates for offices, conference rooms, and facilities

Online Stores & E-commerce Brands – Personalized products, limited runs, and on-demand customization

Gift Stores & Boutiques – Premium engraved items with lasting detail and contrast

Promotional Items & Swag – Logos and messaging on metal drinkware, tools, keychains, and accessories

Corporate Gifts – High-end, personalized gifts for clients, partners, and employee recognition

Event & Conference Giveaways – Durable branding that outlasts printed or coated alternatives

Private Label & White-Label Products – Clean, consistent marking for resale and brand expansion

Fiber laser markers provide permanent traceability and identification on hand tools, dies, molds, and machine components. High-contrast serial numbers, barcodes, and DataMatrix codes are engineered to withstand abrasion, heat, chemicals, and harsh industrial environments, ensuring long-term readability and compliance.

A galvo fiber laser marker uses high-speed galvo mirrors to rapidly steer the laser beam. This enables fast, precise marking, making it ideal for serial numbers, barcodes, and high-volume production for marking on-the-fly.

Fiber laser marking machines generate a laser beam using a seed laser and amplify it in specially designed glass fibers. Fiber lasers produce a wavelength of 1.064 micrometers, which allows for a small focal diameter and high intensity.

These terms are often used interchangeably, but they describe different results and processes:

Laser Marking - A broad term for changing the surface appearance of a material without removing significant material. This includes color change, oxidation, or surface annealing. Marking is fast, precise, and ideal for barcodes, logos, and serial numbers.

Laser Etching - A subset of engraving where the laser melts the surface, creating a slightly raised, high-contrast mark. Etching is faster than deep engraving and commonly used for coated or anodized metals.

Laser Engraving - The laser physically removes material, creating depth. Engraving is more permanent and tactile, making it ideal for parts that must remain readable after abrasion, heat, or chemical exposure.

In short: Marking changes appearance → Etching lightly melts → Engraving removes material.

A standard fiber laser uses a fixed pulse, while a MOPA fiber laser allows adjustable pulse width. This gives MOPA lasers better control for color marking on metal, cleaner plastic marking, and finer engraving detail.

The primary difference between UV lasers and traditional fibers lies in the wavelength of the light they emit. Fiber lasers generally operate in the infrared range, around 1064 nm. This wavelength is suitable for engraving or cutting a variety of materials, but can cause more thermal damage due to the wavelength being longer, leading to undesirable material damage (burning, scorch marks, etc).

In contrast, the shorter wavelengths of UV lasers allows for more precise lasering without significant heat generation, preserving the integrity of surrounding material.

Yes, some plastics can be marked with a fiber laser, but results vary by material. For better contrast, reduced burning, or color control, MOPA or UV lasers are often the better choice.

EMP Fiber laser marking machines can achieve a precision of up to 0.01mm., depending on the lens, material, and system configuration. Some fiber laser marking machines can achieve precision levels of up to 0.001mm, which is significantly higher than diode lasers.

Yes, on certain materials.

Fiber lasers can create multiple colors on stainless steel and some alloys through a controlled oxidation process called annealing or color marking. By carefully adjusting power, speed, and frequency, the laser alters the oxide layer thickness, producing colors like blue, gold, bronze, red, and green.

On plastics, additives in the material can cause contrasting light or dark marks.

However, not all metals or plastics support color marking, and pure black or white marks are still the most common and highest contrast for industrial applications.

Fiber laser markers excel with metals and certain plastics, including:

Stainless steel

Carbon steel

Aluminum (anodized and bare)

Brass

Copper

Titanium

Nickel alloys

Coated and plated metals

ABS

Polycarbonate

Nylon

Polypropylene (with additives)

PVC (with proper fume extraction)

Fiber lasers are the gold standard for metal marking because they:

Emit a 1064 nm wavelength, which metals absorb extremely well

Produce permanent, high-contrast marks

Deliver exceptional precision for fine text, logos, and DataMatrix codes

Require no consumables (no inks, chemicals, or tooling)

Offer long service life (often 100,000+ hours)

Maintain consistency at high speeds for industrial throughput

This makes fiber lasers ideal for manufacturing, aerospace, medical devices, automotive, electronics, and tool marking.

Several laser technologies are used for marking, depending on the material:

CO₂ Lasers - Best for wood, glass, rubber, leather, paper, and acrylic. Not effective on bare metal.

UV Lasers - Ideal for ultra-fine, low-heat marking on plastics, glass, silicon, and medical components.

Green Lasers (532 nm) - Useful for reflective metals like copper and gold, especially in electronics.

Dot Peen or Mechanical Marking (non-laser) - Uses physical impact instead of light; durable but less precise and noisier.

Each technology serves a purpose, but fiber lasers dominate metal marking due to speed, durability, and operating cost efficiency.

Very little. EMP fiber laser systems are air-cooled and require no consumables or routine servicing.

Yes, EMP fiber marking machines work with LightBurn and most design software.

The marking software for fiber laser machines operates similarly to a printer driver, allowing for easy integration with various graphics and CAD software.

Yes, please see our Financing page for details.

Whether you're producing serialized components or premium branded products, EMP Laser fiber markers give you the control, consistency, and finish required for professional results.

Talk to Our Team