A History of Innovation

Foundation

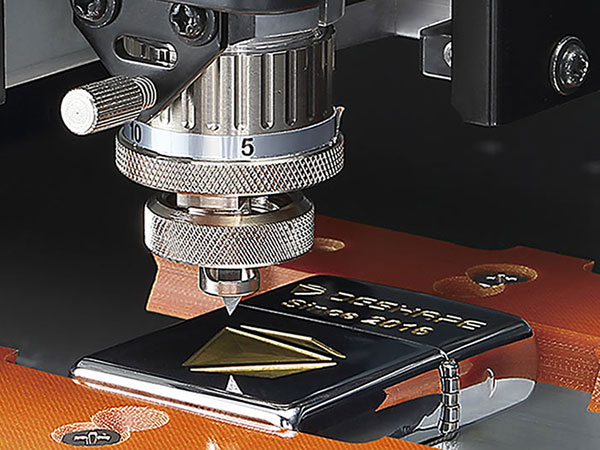

Founded in 2008, EMP Corp. began as a supplier of engraving equipment, providing businesses not only with top-tier machines but also with the installation and training needed to maximize their value. Through years of successful partnerships and satisfied clients, EMP evolved from its beginnings in rotary engraving technology, finding its niche in the laser industry. Focusing on laser engravers and cutters, EMP quickly built a reputation for delivering high-quality equipment, exceptional customer support, and a dedication to innovation that has driven its success.

Strategic Partnerships

After partnering with several laser manufacturers, EMP solidified a strategic alliance with Aeon Laser, eventually becoming its exclusive U.S. distributor. This relationship marked a turning point for EMP, helping Aeon become a major name in the laser industry. More than just a distributor, EMP invested heavily in research and development, driving new technologies to make laser systems more user-friendly, reliable, and efficient.

Innovations

Multi Roller Rotary

Among its notable innovations, EMP launched the Multi Roller , an industry-first tool that enables users to engrave multiple stainless-steel tumblers simultaneously— a significant boost in efficiency and productivity for engravers of all types.

Iris System

The drive to enhance fume extraction led to the development of the Iris System, a pioneering technology that automatically switches between upper and lower extraction zones, providing precise and effective fume management.

EMP Touch

Most recently, EMP introduced the EMP Touch, an intelligent rotary device designed to eliminate cumbersome setups by streamlining the fixturing of cylindrical items, while also enhancing repeatability and batch processing.

Proprietary Products

EMP has also released a line of proprietary consumable products, including acrylic, wood, faux leather and tumblers. Plus, a collection of supplementary products like a material storage cabinet, plug-and-play air compressor, hat press, water chiller guard, wireless networking device, and a laser fire suppression system TBD.

Groundbreaking Achievements in CO2 Laser Technology

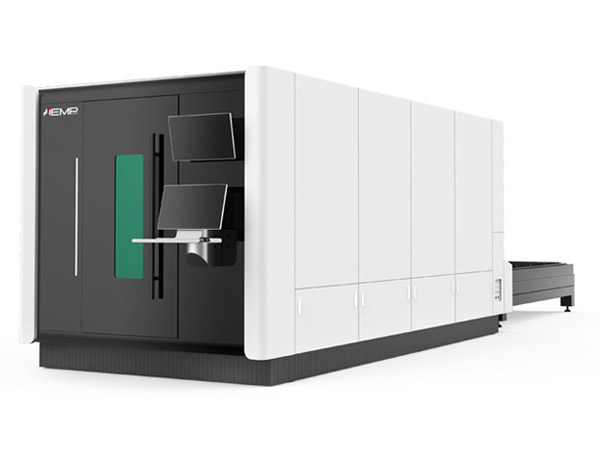

Perhaps the most prestigious of EMP’s most groundbreaking achievements is the release of the EMP Signature Series, the fastest and most reliable CO2 laser system available on the market today. Built on the chassis of the new Aeon Redline Series, EMP takes it to a whole new level with an ensemble of American made components designed to meet the needs of professionals who demand faster cycle times and unwavering results. The assembly process is carried out by a single EMP technician who then proudly signs it upon completion.

Making Metal Fabrication Accessible

Expanding beyond CO2 lasers, EMP has ventured into fiber laser technology, introducing fiber marking machines, welders, grinders, and sheet metal cutters. By bringing affordable sheet metal cutting technology to the sign industry and other smaller operations, EMP is opening new revenue streams for smaller shops, making metal fabrication accessible to businesses that once found it out of reach.

The Future

With an impressive track record of innovation, quality, and affordability, EMP Corp is setting new standards in the laser industry. By focusing on making advanced laser technology accessible to businesses of all sizes, EMP continues to shape the future of laser engraving, cutting, welding, and marking.