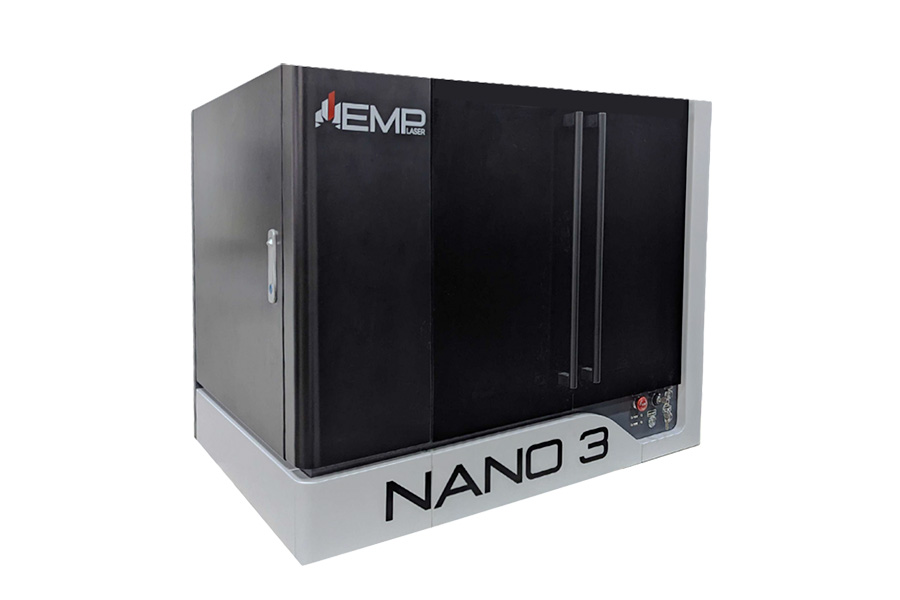

EMP Nano Enclosed Tabletop Fiber Laser Cutter Nano 3

The EMP Nano is an enclosed tabletop unit designed for jewelers, educators, and manufacturers working with small parts. Its space-saving footprint and high-accuracy performance make it perfect for fine detail work in any professional or learning environment.